Green Watch

America’s Rare Earth Ultimatum: A Solution to Rare Earth Market Failure

America’s Rare Earth Ultimatum (full series)

Rare Earths in High Demand | Made in China | A National Policy of Vertical Integration | A Solution to Rare Earth Market Failure

Summary: For the past decade, our dependence on rare earths has conjured up considerable attention, fascination, and concern regarding their importance. This has caused a cascading effect to create interest and investment in other rare metals, critical minerals, ore deposits, mining, and the American mineral endowment—all related to with U.S. technology manufacturing, national security, military readiness, geopolitics, and trade, particularly with China. Rare earth elements have become the poster child for critical minerals, especially those for which we are 100 percent import dependent—the vast majority of which come from China.

Re-Visiting Regulations Gone Awry

Forty years ago, the U.S. was the world leader in the production of rare earth oxides and critical metallurgical materials derived from rare earth metals. Then, the International Atomic Energy Agency and the Nuclear Regulatory Commission agreed to apply the label of “source material” (i.e., radioactive source material) to all mine tailings (waste rock) that contained concentrations of radioactive thorium or uranium above .05 percent content. The regulations define any processed or refined material with thorium and/or uranium concentration above .05 percent as source material.

They could be enforced because virtually all countries were members of International Atomic EA, especially mining countries. Specific to the U.S., the Nuclear Regulatory Commission further upgraded U.S. safeguards on nuclear material, mirroring the International Atomic Energy Association regulations. The Nuclear Regulatory Commission’s language includes all U.S. mine tailings and material processing, not just tailings from uranium mining.

Because rare earth production is typically associated with the thorium and even uranium content from the same ore materials, the new regulations meant that rare earths, especially heavy rare earths, would no longer be processed from mine tailings that exceeded the .05 percent source material concentration limit. The regulations would also prohibit rare earths processing from phosphate tailings because of their thorium content, when in excess of .05 percent.

As a result of the Nuclear Regulatory Commission and International Atomic Energy Association regulations, virtually all heavy rare earth production now unexpectedly met the technical definition of a “source material,” causing these resources to be withdrawn from the domestic supply chain.

But there was no outcry over the regulatory change; compliance began worldwide. In the U.S., for example, byproduct producers and domestic supply chain consumers of these materials, such as phosphate deposits, never informed federal regulators or Congress of the looming problem, because of concerns over the potential legal, environmental, and health liabilities associated with decades of unregulated thorium disposal.

To conform to the new regulations, mining operators took the path of least resistance and buried the tailings along with their rare earth content. Some miners devised various processes to dilute or blend thorium-bearing rare earths below threshold and background radiation levels.

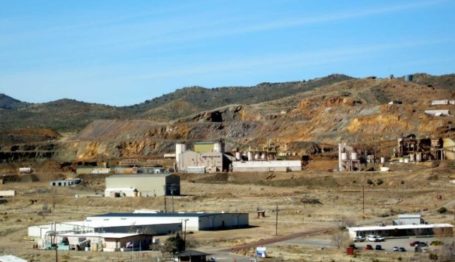

For the most part, costly burial of rare earth resources continues today, such as at Florida phosphate mines, even though rare earth materials are recoverable. Light rare earths, like those found in the Mountain Pass deposit, contain low levels of thorium below the threshold and were unaffected by regulations. However, the outcry over the 300,000-gallon spill of a thorium-enriched solution across the adjacent desert floor contributed to the mine’s demise and initial closure in the late 1990s.

Meanwhile, the situation in China was more promising for the explosion of their rare earth industry because:

- China was not a member of the International Atomic Energy Association in 1980, and therefore not bound by the new source material regulations implemented for the rest of the world.

- The International Atomic Energy Association source material regulations do not apply to a certain class of rare earth deposits which are most prevalent in China. Most Chinese rare earth production is a byproduct of iron ore mining; because it contains low thorium levels (less than .25 percent by weight thorium and/or uranium), it is exempted from the regulations.

Ironically, China did become an International Atomic Energy Association member in 1984—a point at which politically they had everything to gain and nothing to lose on the world stage since their industry was already grandfathered in. In retrospect, geologic serendipity and the International Atomic Energy Association regulations handed China a dual rare earth monopoly by exempting their domestic rare earth mining program and their metallurgical processing of finished products.

The result was that all rare earth resource mining and supply chain production quickly shifted to China. However, at that time, concern among business leaders outside of the mining industry was at a minimum because rare earth technology, metallurgy, and the importance of magnet applications for electronics were still in their infancy. Looking back on this situation from today’s vantage point, it is clear that only a handful of experts in the U.S. fully grasped the groundbreaking potential for rare earth materials in the 1980’s, but it was too late—China was already in control.

China’s rare earth monopoly would probably never have been established without the needless misapplication of Western-minded, environmentally sensitive regulations.

At present, no new stand-alone mine could be expected to produce rare earths at a lower cost than China. The one possible exception might be the Bear Lodge in northeast Wyoming. When that mine comes online, the combination of high-grade ore deposit and patented processing techniques would probably be competitive with Chinese rare earth ore production.

In the end, China’s rare earth monopoly is not simply a resource issue, where they have most of the world’s rare earth ore deposits and other countries do not. On the contrary, many operating mines in the U.S. and worldwide which produce basic commodities, such as phosphates, titanium, zircon and iron ore, annually dispose of enormous quantities of tailings that contain major quantities of recoverable rare earths, as explained above. This proven recoverable resource is estimated to represent the equivalent of approximately 65 percent or more of global rare earth demand.

Therefore, opening new mines to obtain these rare earths is not necessary if the rare earth content of selected existing mine tailings can be processed before disposal.

To harness this rare earth resource gift, creative solutions are desperately needed and some are now being developed. The first step in the arduous process of breaking the Chinese monopoly will be to somehow roll back or sidestep the 40-year-old Nuclear Regulatory Commission regulations and mitigate their harmful unintended consequences.

American Rare Earth Ingenuity

Domestic mining is not a short-term solution for obtaining rare earth materials, because mines can take years to become operational due to excessive permitting and time-consuming infrastructure construction. U.S. rare earth miners often have tried to compete in the mining arena and been bankrupted in the past by China, even though they have abundant rare earth reserves in the form of mineral deposits, and as byproducts from other minerals.

The processing and manufacturing supply chain to turn those mineral ores into useable parts is the main problem in the United States. It’s also the fulcrum of China’s successful rare earth monopoly.

Thus, a pressing question for the new administration and Congressional representatives shaping budget priorities and offering regulatory oversight is how best to address our rare earth over-reliance on China, a strategic competitor, and ensure that the U.S. will have a secure supply of rare earth ore and processed rare earth metals and materials. Building a domestic U.S. rare earth industry—from mine to marketplace—to meet the nation’s technology manufacturing requirements will still encounter the inevitable mercantilist Chinese manipulation of rare earth pricing and the global supply chain.

It can be built . . . but it will require American ingenuity!

There are four significant problems to overcome:

- Direct mining of rare earths would unfairly face and compete with state-sponsored monopoly pricing from China, so any mine’s economic viability or long-term sustainability is highly questionable.

- Congress and successive Administrations have failed to establish a public-private sector mechanism for utilizing our abundant legacy resources, rather treating them as toxic waste with expensive and inherent liabilities.

- Even if U.S. legacy resources were tapped, there is no fully integrated value chain outside of China with the capacity and capability to convert these resources into usable oxides and metals.

- Like direct mining, the economic viability of a domestic, market-based manufacturing value chain is unrealistic, considering China controls global pricing and supply of all finished rare-earth materials, and would not have any motivation to cease its successful monopoly.

The above issues reflect what western economists would refer to as a “market failure.” There are many reasons for market failures, including competing against state-sponsored monopolies. They are typically managed through the creation of shared risk, production, and distribution platforms called “cooperatives.”

One suggested solution would be to form a U.S.-based, privately funded and managed rare earth cooperative. The co-op would be comprised of technology companies that require rare earths to manufacture magnets, electronics, alloys and rare earth metals—and would focus strictly on turning rare earth ores into oxides metals. The proven advantage to this kind of co-op is that it would enable end-users—the technology manufacturers—to act together, without violating antitrust law, to procure finished products that currently are unavailable domestically.

Cooperatives have long been an American solution to market failures. For example, new-generation cooperatives (NGC), developed in the 1990s in California, the Midwest, and elsewhere are tailored specifically for use by modern capital-intensive industries that add value to primary products, such as those involved in the production of ethanol from corn, or juice products from citrus crops. Energy distribution fits into this model very well.

A properly constructed rare earth co-op could redirect the flow of capital, jobs, and the newest processing and refining technology related to the rare earth industry away from China and toward a reliable domestic solution—a highly desirable goal for this totally import-dependent group of minerals. In so doing, a rare earth co-op would be historic, and would represent a slice of American ingenuity and willpower that could not be stopped by Chinese manipulation.

In the final analysis, China can hardly be blamed for its clever use of global mineral resources. Decades of unsustainable U.S. mineral resource policies contributed mightily to its success and to our nation’s present state of wild over-reliance of many critical minerals. If a rare earth cooperative proves as successful as other American co-ops, not only would it alleviate rare earth supply problems, but it could represent a template for domestic production of other import-dependent critical minerals in the unforeseeable future.

The Trump administration has pledged its commitment to embark on a massive infrastructure rebuilding program. Minerals and metals are the backbone of the nation’s infrastructure. With our national security at stake, bold and resourceful action to create a domestic rare earth supply chain using co-ops might be the best plan where none now exists.